Aquaponic System

A basic aquaponic system creates a natural cycle where fish and plants grow together in harmony. Fish provide nutrients for the plants, while the plants clean the water for the fish. Using minimal space and resources, it’s an efficient, sustainable way to produce fresh food year-round — perfect for homes, schools, or community spaces.

✅ Strengthens Local Food Resilience

By producing fresh food year-round, aquaponics reduces reliance on global supply chains.

✅ Protects Our Oceans

Sustainable fish farming eases pressure on overfished wild populations.

✅ Saves Water and Energy

Aquaponics uses up to 90% less water than traditional farming, preserving vital resources.

Get started

Starting an aquaponic system is easier when you know the essentials.

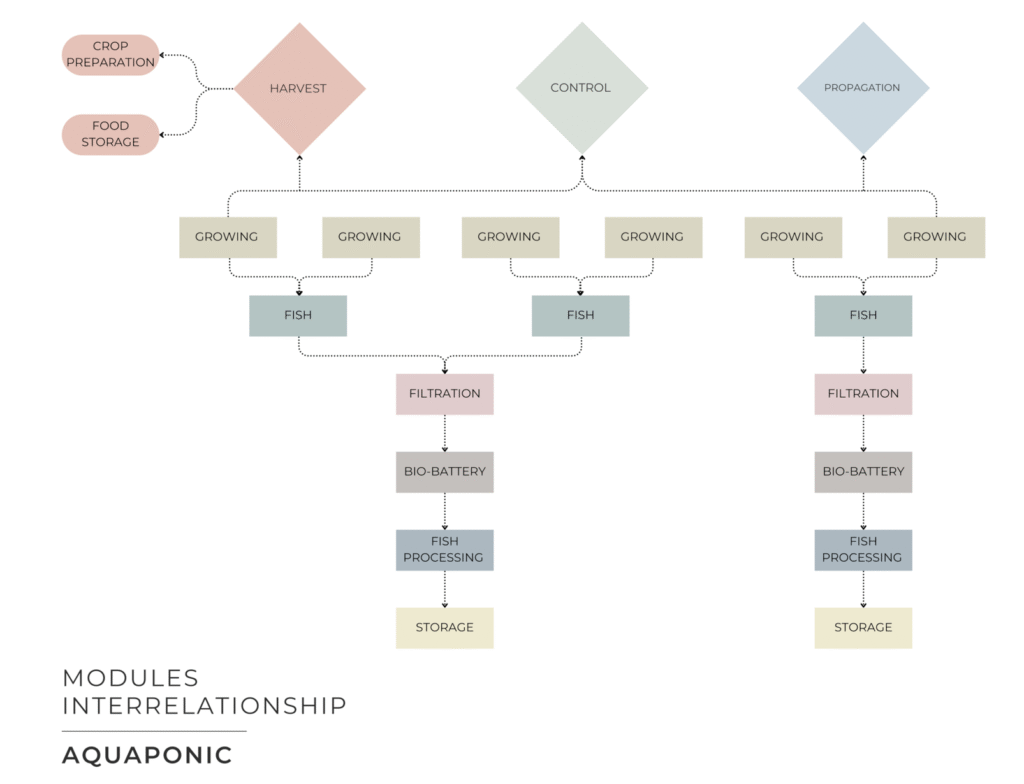

Below is an infographic followed by a list of the basic modules you’ll need to create a balanced, thriving setup where plants and fish support each other naturally.

Learn more about the benefits of soilfree systems Turf Hubs ->

Modules

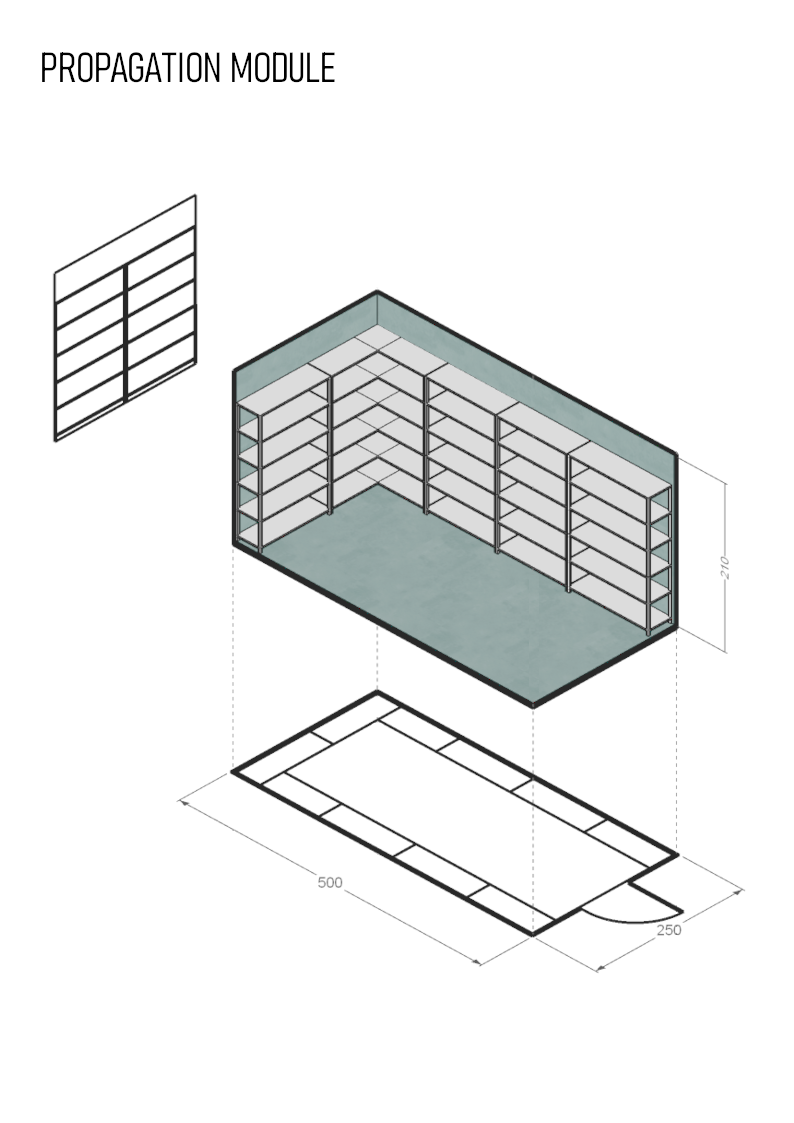

Propagation module

Before the growing module in the system can grow crops, it is essential that the seeds are first propagated. This is to ensure the seeds are grown in a specific environment beforehand to assist with their early development.

This is typically conducted in a propagation area, which is kept separate from other areas for cleanliness and ease. Once the seeds have germinated and have developed their first seed leaves, or a small number of true leaves, they can be transplanted into the growing module, where they will receive nutrients from either the aquaponic or hydroponic equipment.

Seeds can be propagated in very high densities, which means a whole farm only needs a very small area for these activities.

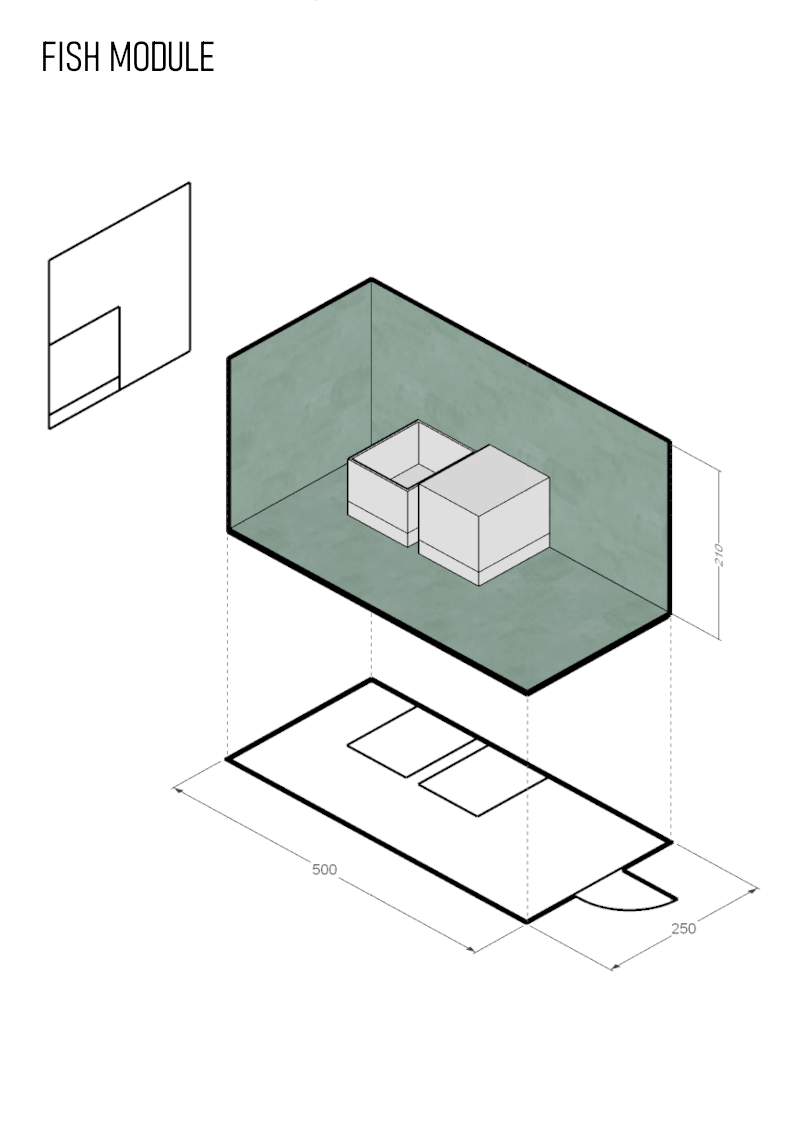

Fish modules

Aquaponic systems require fish to be fed to create ammonia. The ammonia can then be converted in nitrite and later nitrate by bacterial processes, which makes nitrogen available to crops. This process is referred to as ‘biological filtration’.

Solid waste is also produced by the fish, but this needs to be removed from the system as it takes much longer to be break down into available nutrients, and can become harmful the system if not removed. The solid waste is removed through a process called ‘mechanical filtration’.

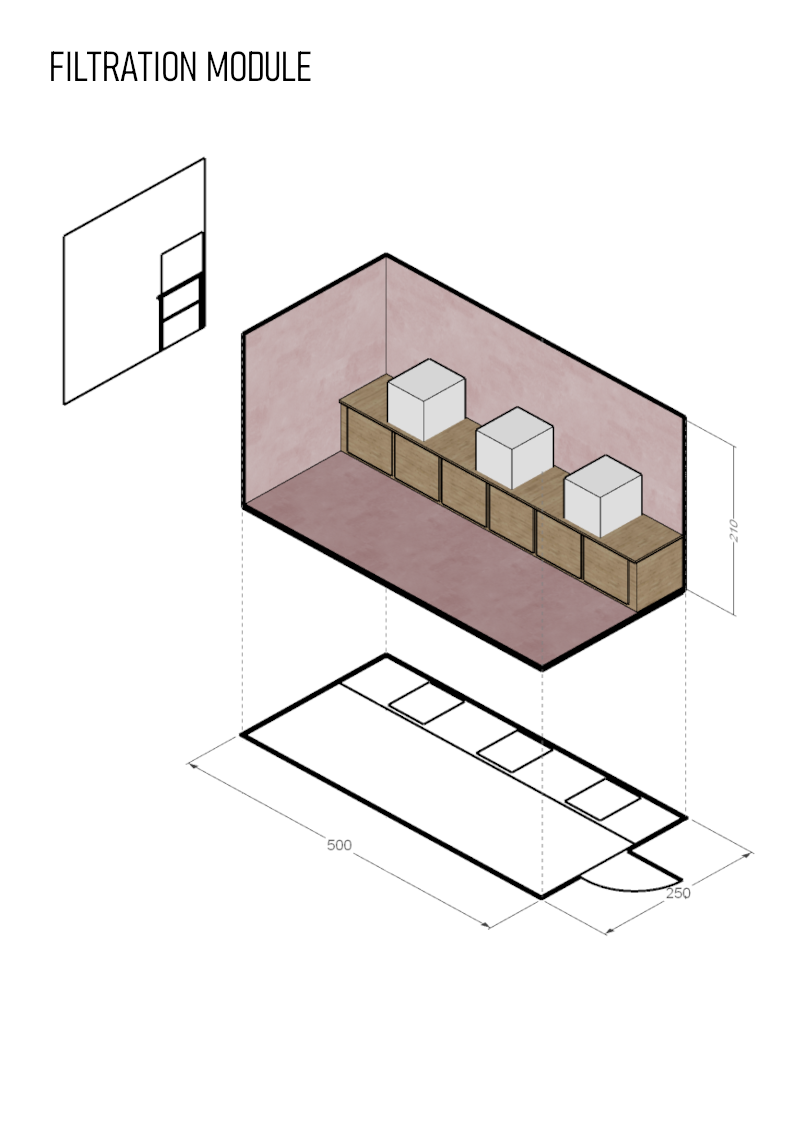

Filtration modules

The filtration module is used specifically alongside the fish module in an aquaponic system to process the waste produced by the fish. This module includes mechanical and biological filtration steps to achieve this.

The mechanical filtration can use a range of different approaches, such as simple filters that capture solid waste as it passes through, which require regular cleaning, a series of baffles or separation tanks, which trap solid particles in a particular zone so they can be easily removed, or a radial flow filter that spins the water, which forces solid particles to move to the sides and slowly fall to the bottom.

The biological filtration process uses a media with a very high surface area, such as expanded clay balls (leca) or a specially produced plastic biomedia. These medias create a large surface area for bacteria to colonise, which allows them to convert the ammonia into nitrite and nitrate, at the rate required to protect the fish and produce nutrients for the crops.

The water in an aquaponic system continually recirculates, taking the harmful ammonia away from the fish, providing a feed to bacteria, and creating nitrogen for the crops. The water then returns to the fish in a fresh state for the cycle to repeat again

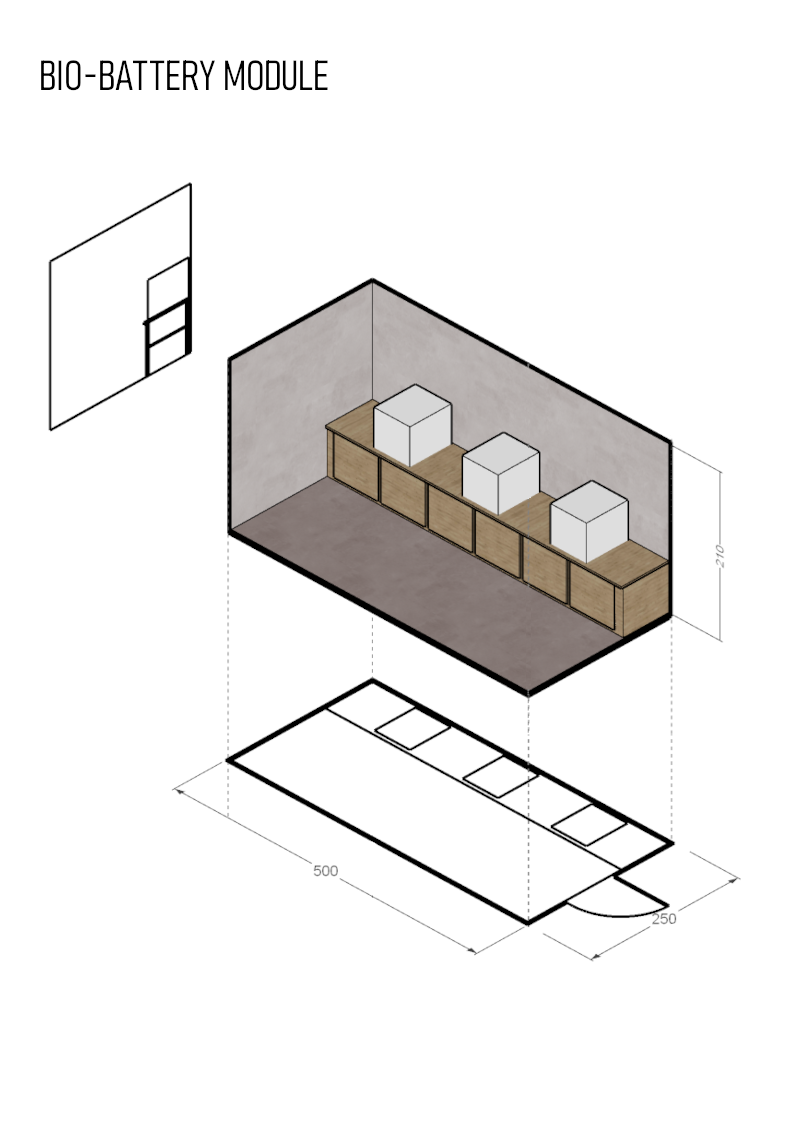

Biobattery modules

The bio-battery module uses a material called ‘biochar’ to sequester excess nutrients from the aquaponic system. The biochar acts like a sponge to soak up these nutrients, which would be detrimental to the system if left to accumulate.

This allows the fish to be fed as a higher rate than the system could otherwise handle, which leads to two outcomes. Firstly, the fish can grow more quickly and be harvested more often. Secondly, the nutrient-rich biochar can be used as a soil conditioner in gardening or horticulture, providing an additional revenue stream.

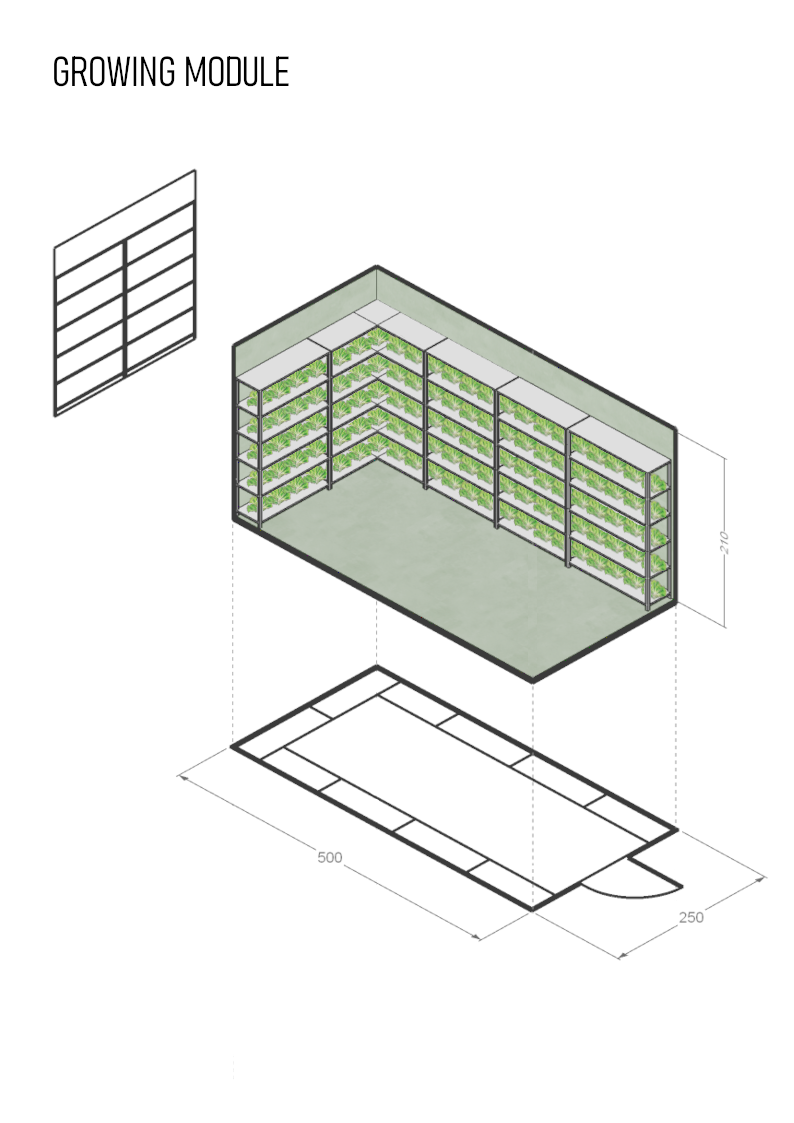

Growing modules

In the growing module, will be vertically stacked shelves and artificial lighting.

Growing modules will produce leafy greens using soilless systems; either aquaponic or hydroponic. In this example we list modules needed for an aquaponic system to work.

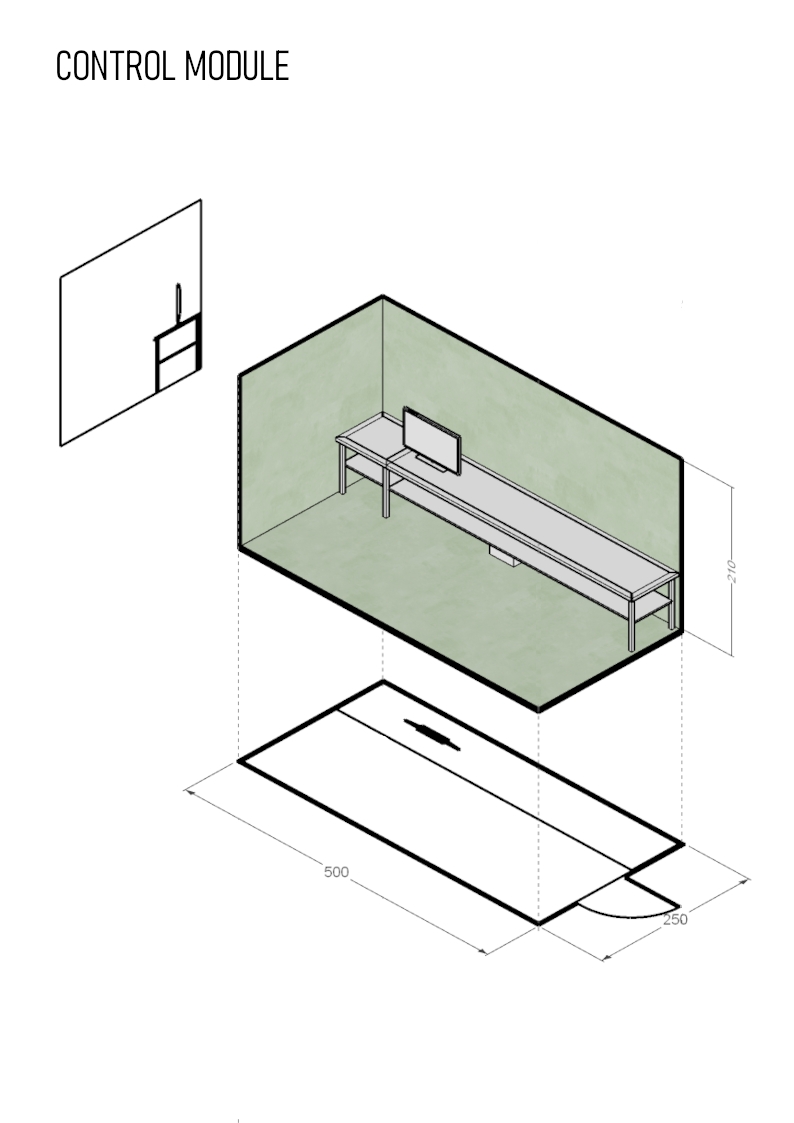

Control module

The indoor climate will require constant set points of temperature, humidity, and carbon dioxide (or oxygen for mushrooms), which will be maintained by a control module.

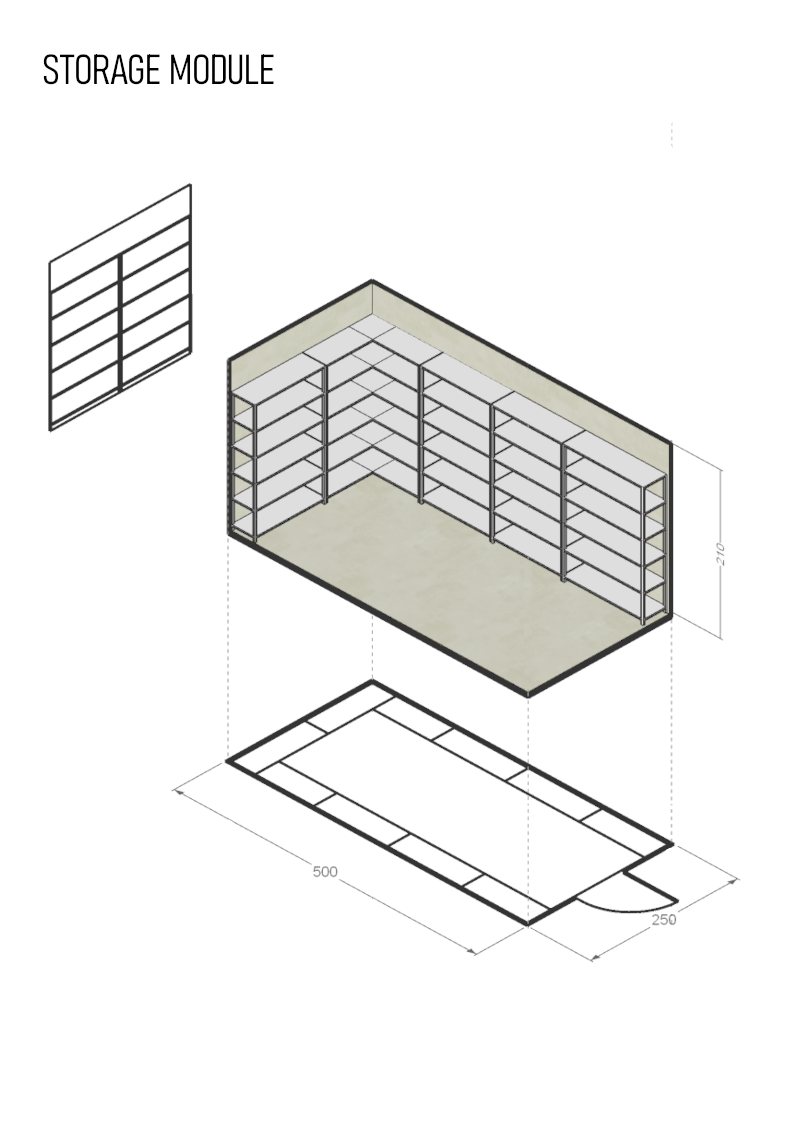

Storage module

As with any business, storage is required to provide a short- to long-term home for all the materials required to run said business.

In the case of this urban farm, storage is required to store seeds, growing substrates, tools, cleaningand maintenance equipment, fish food, etc.

It is anticipated that the size of the module should be ten percent of the overall footprint of the urban farm, with a minimum size of one car parking bay.

.